How to Improve OEE ? Author : Cengiz Özden | M.Sc. Control and Computer Engineer CTO

What is OEE?

OEE (Overall Equipment Effectiveness) is a significant tool of Lean Manufacturing and TPM (Total Productive Maintenance).

OEE highlights the “major losses” in the manufacturing process to regain “hidden capacity.” Improvement of OEE means loss reduction and production capacity improvement.

In order to improve OEE, we need to focus on its components: Availability, Performance and Quality.

Availability factor represents stoppage losses such as breakdowns or equipment failures, changeovers (setups, adjustments) and waits.

Performance factor represents the losses caused by minor stoppages and speed reductions.

Quality factor represent defects/NOKs/rejects/scraps including rework.

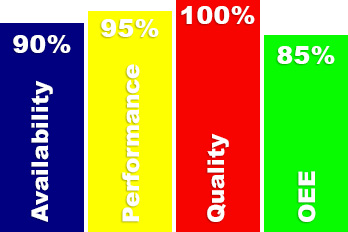

World class percentage targets are as follows; 90 percent Availability, 95 percent Performance, 99 percent Quality, which result in 85 percent OEE. These numbers are defined based on practical experience, as minimums for which companies should strive for. All of the companies that won the Distinguished Plant Prize, which is an award given annually in Japan to plants that had successfully implemented TPM, had OEE scores of more than 85 percent.

World class percentage targets are as follows; 90 percent Availability, 95 percent Performance, 99 percent Quality, which result in 85 percent OEE. These numbers are defined based on practical experience, as minimums for which companies should strive for. All of the companies that won the Distinguished Plant Prize, which is an award given annually in Japan to plants that had successfully implemented TPM, had OEE scores of more than 85 percent.

The reality is that most manufacturing companies, even today, have OEE scores closer to 55 percent. We work with hundreds of manufacturing companies and we see more companies with OEE scores lower than 45 percent compared to companies with OEE scores higher than 75 percent.

How to improve OEE?

Improvement activities can be grouped as;

1. Firefighting

2. Fire prevention

In case of a fire, we need to take immediate action to extinguish it. Next action should be to work on how to prevent a similar fire from erupting.

Instant data helps us in firefighting. If we have speed reduction problem at a machine, we need to know it at the moment of the incident. This way, we can take immediate action and minimize the loss.

To prevent fire, we do 6 sigma projects or kaizen. The excellent plant is not the one with the fastest/biggest firefighting team.

Another grouping can be stated as;

1. Perceptual

2. Systematical

Perceptual improvements are easy apples which are at the bottom branches of an apple tree. If you are aware of a problem you can solve or improve it. Most of the perceptual improvement ideas come from the workers themselves and they are less likely to be radically different, therefore making them easier to implement. Small improvements are less likely to require major capital investment than major process changes.

Systematical improvements are feed by analysis. For analysis, we need detailed and trusted data.

Tools to help improve OEE

As ProMANAGE we supply powerful tools to help you improve OEE.

Trusted and Instant Data

The core system is based on automatic and real-time data collection from the machines. We minimize human dependency on data collection.

In many manufacturing plants, production data is gathered via forms and manually. Managing team found many inconsistencies on the reports so they cannot trust that data. In addition, forms are collected at the end of each shift and the reports are becoming available with at least one shift delay.

Trusted data is indispensable for management to make healthy and correct decisions.

Analysis on Trusted Data

ProMANAGE obtains detailed and trusted data and offers detailed and trusted analysis reports.

ProMANAGE provides a rich variety of analysis reports, which enables you to identify your losses and discover the potentials for systematical improvements. These reports help prevent fires.

Visualization Instant Data

Visualization Instant Data feeds perceptual improvements. Nearly all manufacturing plants have operational excellence experts. They are equipped with all sorts of requirements for improvements. However, when the workforce is not aware of problems, it falls short. ProMANAGE’s Andon/Dashboard solutions provide instant visualization on the shop floor for operators and shift leaders in order to create awareness and improve OEE.

Every manufacturing plant has shift leaders or someone responsible for helping workers with problems. As in every resource, qualified workforce is limited and cannot deal with every incident. Visualization of instant data helps them with focusing on correct areas.

Automatic Escalation

Escalation help us with firefighting. If we have a speed reduction problem at a machine, we need to know it at the moment of the incident. This way, we can take immediate action and minimize the loss.

ProMANAGE’s automatic escalation shortens the response time to problems and directly results in OEE improvement.