Productivity Management in Manufacturing via Digital Tools Author :Ahmet ÇAKIREL, ProMANAGE Manufacturing Operations Management Consultant

PRODUCTIVITY INCREASE IS NOT A TARGET BUT A SOLUTION

In cases when the target is defined as “eliminating the losses that cause unproductivity,” it can be observed in plenty of applications that the outcomes are significantly more desirable.

It’s a necessity to increase productivity

The necessity of increasing productivity is well-known and acknowledged by all factories and individuals regardless of their sectors. When the increasing competition environment and customer needs are taken into account, it’s apparent that increasing productivity in the manufacturing sector is not an act depending on preferences, but it is instead a necessity.

However, setting the main and sole target as increasing productivity is not sufficient to obtain positive outcomes. Productivity increase is more of an outcome rather than a target. In cases when the target is defined as “eliminating the losses that cause unproductivity,” it can be observed in plenty of applications that the outcomes are significantly more desirable.

Q: How should it be done?

A: Analyzing losses to increase productivity, setting the right target, analyzing the causes of the losses that are set to be eliminated and taking action must be carried out via operating a cyclical process and in continuity.

Q: How can digital tools help productivity increases?

A: The tools that ensure automatic functioning of the improvement cycle are extremely effective in increasing productivity due to their ability to provide continuity. ProMANAGE Manufacturing Operations Management (MOM) System is equipped with the tools to support each step of this process. ProMANAGE, which ensures instant monitoring and removal of the losses in factories, makes sure that appropriate actions are taken for the prevention of future losses before they occur through analyzing the losses that took place in the past.

How does ProMANAGE support productivity management?

Thanks to the system’s Online Monitoring Tools and Incident Notification Service, the losses that are occurring can be monitored instantly, information flow can be ensured and necessary action can be taken as soon as possible. For instance, in addition to the ability to instantly monitor the machines at stoppage status through coloring made according to their stoppage categories, the demonstration of the stoppage and its cause with all of its details ensures that necessary action is taken without delay for the removal of the stoppage cause. With the AndonLCD screens that are situated at the manufacturing area and at the necessary departments, machinery’s requirements can be shared with the entire team and awareness can be raised. In addition to these, with its standard and special applications aimed at meeting requirements, ProMANAGE ensures that the machinery can convey its requirements through a high number of warning tools.

Duties of Users

Instant response to losses and their removal are significant. However, to prevent these losses before they occur is more important. Each loss can be thought of as a fire in terms of productivity and profitability. While it’s very important to extinguish the fire as soon as possible, it’s also extremely essential to adopt measures to prevent a fire from erupting.

Instant response to losses and their removal are significant. However, to prevent these losses before they occur is more important. Each loss can be thought of as a fire in terms of productivity and profitability. While it’s very important to extinguish the fire as soon as possible, it’s also extremely essential to adopt measures to prevent a fire from erupting.

Main issues that require special attention

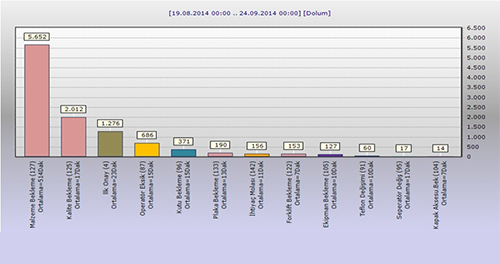

Utility and quality losses, more specifically stoppages and scraps, are the main factors that cause productivity losses in manufacturing. Prevention of stoppages and scraps before they occur is possible with the determination and removal or improvement of the elements that cause them. ProMANAGE Manufacturing Operations Management (MOM) System presents the data would provide the basis for Lean, TPM and 5S works to the user through analyzing the losses. With the Pareto analyses that the system provides, the user can determine the loss that needs primary intervention and therefore obtains a hierarchy of needs regarding the losses. In Pareto analyses, the determination of targets via ensuring prioritization of the indicators, such as duration, percentage, amount and FR, through listing them in their categories bears significance. It’s necessary for the target to be digitized and embraced by the whole team. After the determination of the loss that will be addressed, the search for the root causes that lead to the loss and implementation of cross-examinations, in other words the 5Ws & 1H method, bears a significant role in terms of determining the actions that need to be taken for the elimination of the loss and setting a numerical target. ProMANAGE provides the opportunity to find and eliminate/enhance the root causes of the loss thanks to its big data analysis data that it carries out and presents numerically and graphically for the manufacturing sector, in which plenty of elements take part. The system, which ensures the tracking and identification of the targets based on time, machine and all components, helps in taking necessary actions to prevent losses before they occur instead of eliminating them before they increase.

Productivity will continued to be lost as long as the root causes of the losses are not analyzed and eliminated afterwards. The elimination of losses must be the main target in all areas that increasing productivity is the aim.