Industrial PC Screens’ Contributions to Operators and Manufacturing Author : Ahmet Çakırel, Manufacturing Operations Management Consultant

Importance of Data Input

In order to carry out manufacturing follow-up and productivity analyses, five types of data are collected from the machinery with ProMANAGE Manufacturing Operations Management (MOM) System in the simplest scope. The first data, “Signal,” are gathered from machines automatically. Signals can be collected over KeyPDT, Smart Counter or OPC Servers. The other four data consist of information on operator, work, stoppage and scraps that are provided by operators. These data can be obtained from the KeyPDT devices or Industrial PC screens.

For the follow-up of production amounts, appropriate selection of work information is just as important as obtaining the true signal from the machinery. In order for production to be carried out for appropriate purchasing order and work order, for the functioning work’s speed information to be appropriate and for the stoppage and operating analyses to bear correct results, work selection must be correctly made. In addition, the appropriate analysis of losses is possible with the appropriate data input. In this sense, it’s significant for an operator to make easy data input.

Conveniences Provided by Industrial PC Screens to Data Input

KeyPDT and Industrial PC screens were designed to facilitate making data inputs for operators. However, the KeyPDT screen doesn’t aim for any visuality, guidance or warning and instead, it only assumes the duty of being the functional interface for data input. Because the Industrial PC interface has no size limitations, the data that will be shown to an operator can be more extensive. For instance, while selection is made with codes on KeyPDT screens, on Industrial PCs, description lists can be shown, tree-structure hierarchical selection can be made and explanations can be entered after the operator makes a selection.

Operators’ Owning Up to Machines and Operation

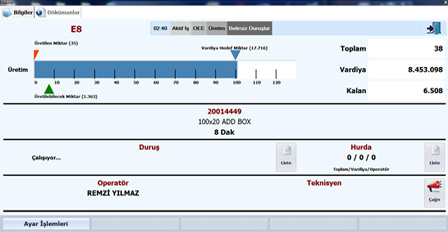

In addition to ensuring selection easiness in data inputs, Industrial PCs take on the mission of making operators aware of the instant status of their machines with the productivity and performance values that are shown, as well as making them own up to their operations. The realized production information is not the only thing presented on a manufacturing screen; through demonstrating the target production values of the time passed since the shift target production and operator input is made, the operator is ensured to track whether he is ahead or behind the set target. When a stoppage of which the target duration is determined is selected, the remaining stoppage target duration is shown via visualization of the target duration. This helps target compatibility and improvement activities.

In addition to ensuring selection easiness in data inputs, Industrial PCs take on the mission of making operators aware of the instant status of their machines with the productivity and performance values that are shown, as well as making them own up to their operations. The realized production information is not the only thing presented on a manufacturing screen; through demonstrating the target production values of the time passed since the shift target production and operator input is made, the operator is ensured to track whether he is ahead or behind the set target. When a stoppage of which the target duration is determined is selected, the remaining stoppage target duration is shown via visualization of the target duration. This helps target compatibility and improvement activities.

In addition to ensuring selection easiness in data inputs, Industrial PCs take on the mission of making operators aware of the instant status of their machines with the productivity and performance values that are shown, as well as making them own up to their operations.

Warning Screens

ProMANAGE user’s demonstration of the information and warning screens that can be designed machine-based to the operator has high added value to making data input healthily and increasing the production performance. Production without operators or works bears importance in terms of data inputs to be made correctly to the warning screens that are shown when the cause of the stoppage is not stated and thus, making detailed loss analyses. Showing instant values of target and realized production, performance and productivity to the operator is the triggering element in increasing productivity performance and gathering operators’ enhancement ideas and feedbacks.

Presentation of Documents

Documents regarding product, operation, mould, stoppage, scrap and similar manufacturing components can be shown on Industrial PC screens. It’s significant for the operator to access related documents’ up-to-date versions from a screen belonging to himself any time he wishes to do so in terms of avoiding production chaos, as well as preventing quality and availability losses without their occurrence. In an environment where customer needs are changing and product revisions and diversities are increasing each day, the significance of related visualization and sharing can easily be understood.

Using Industrial PC with KeyPDT

In addition to the aforementioned added values and features, no signal substructure changes are required for positioning Industrial PC screens on the manufacturing area. Since the Industrial PC screens can be used with KeyPDTs, the current signal collecting method doesn’t change and Industrial PC screens are easily included in the system.