Advantages Obtained with ProMANAGE Manufacturing Operations Management System in the Manufacturing Area Author : Mustafa Turgut, ProMANAGE Manufacturing Operations Management Project Manager

ProMANAGE prevents data loss when gathering data from the area and ensures manufacturing to become more productive by means of making the user save time.

The Value of Manufacturing Data and ProMANAGE

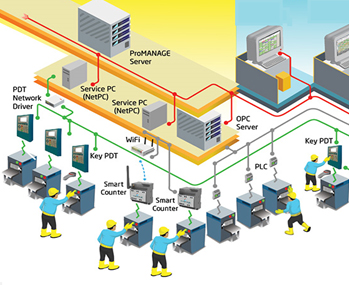

ProMANAGE Manufacturing Operations Management System gathers numbers of different data from the manufacturing area fully and provides the opportunity to link them with production, reporting and managing them. At the point of gathering data from the manufacturing area, three different paths may be followed depending on factories’ needs and positions; gathering data either with KeyPDT, with Smart Counter data gathering terminal or with OPC protocol. The purpose of all of these data collection methods is to form reportings in order to be able to track plenty of variables regarding production and determine the points that will be improved. In addition to all of these benefits, ProMANAGE Manufacturing Operations Management System prevents data loss via automatically gathering data from the area and ensures manufacturing to become more productive by means of making the user save time.

Within the scope of the ProMANAGE system, all works for the automatic data collection from the area are carried out. In addition, at points when a signal can’t be formed either in accordance with the wishes of the customer or due to any other reason, data inputs are carried out on the area manually. All of the values that are entered manually are transferred to the system via operator interfaces. With the automatic gathering of signals and the making of selections via interfaces, wrong data processing is prevented. Contrary to the conventional methods that lead to tracking difficulties and extreme losses of time, a more modern and faultless communication network is being set up with the help of fast and practical interfaces..

Within the scope of the ProMANAGE system, all works for the automatic data collection from the area are carried out. In addition, at points when a signal can’t be formed either in accordance with the wishes of the customer or due to any other reason, data inputs are carried out on the area manually. All of the values that are entered manually are transferred to the system via operator interfaces. With the automatic gathering of signals and the making of selections via interfaces, wrong data processing is prevented. Contrary to the conventional methods that lead to tracking difficulties and extreme losses of time, a more modern and faultless communication network is being set up with the help of fast and practical interfaces..

Advantages of Data Communication with ProMANAGE

In addition to all of these communication advantages, conditioned situations can be established via the generation of various signals from digital outputs located on the KeyPDT and Smart Counter. These outputs can be used for plenty of different scenarios and they can manage operational processes. For instance, desired energy sources of the machines can be halted in accordance with the predetermined stoppages and target durations and thus, wasted energy consumption can be prevented. Responses can be given from these outputs depending on operators’ different needs. Forklift call system, which is another example of usage, can be added to the KeyPDT screen design if requested. With the help of this add-on, the operator can establish a forklift call with a single button from the KeyPDT screen.

With the countless benefits that it provides factories with, ProMANAGE solutions are generating direct income for factories via ensuring major gains on the field. The greatest advantages of the system can be listed as operation simplicity, timesaving, work force gains and information accuracy.