Control and Traceability from Order to Delivery Author : Nedim DUĞANCI, System Analyst

In today’s world, our processes are now more “automatic” due to the increased involvement of PLC technologies in manufacturing processes. So, are we able to benefit from all the blessings that this technology presents us?

In today’s world, our processes are now more “automatic” due to the increased involvement of PLC technologies in manufacturing processes. So, are we able to benefit from all the blessings that this technology presents us?

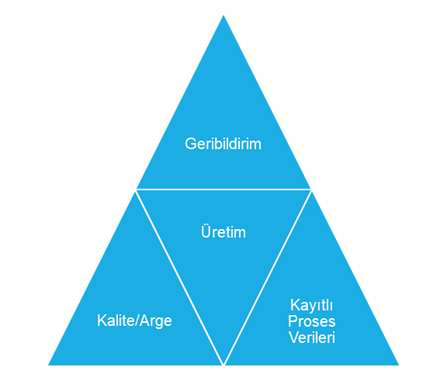

When receiving feedbacks about our products, data, such as under which conditions this specific product is produced, its parameters during production and the raw materials that are used, are undoubtedly becoming increasingly significant for us. Apart from us who want to guarantee the quality of our products, our customers can also demand this data. In addition to these, with the increasing involvement of Industry 4.0 in our lives, our ability to make purchase-specific process settings and productions exclusive to customer demands is starting to become a need that we feel more and more each day.

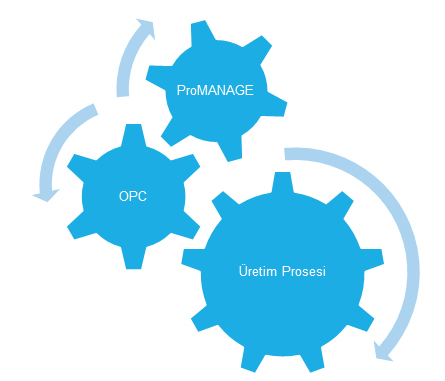

To begin with, as Doruk Automation, we can proudly say that thanks to our MES solutions’ flexible “integration” abilities, they not only can integrate into your existing ERP solutions, but also to your PLC infrastructure for the tracking and control of the aforementioned manufacturing processes, as well as for intervening in them. As a “Corporate Member” of the OPC Foundation that determines the standards and realizes the new developments of the OPC infrastructure, which emerged as an international standard for the data of the PLC systems running in the area to be instantly monitored and intervened in and which is the most widespread communication standard today, our infrastructure is ready to “talk to” your PLCs and we are constantly bringing new technologies to an integrated status.

To begin with, as Doruk Automation, we can proudly say that thanks to our MES solutions’ flexible “integration” abilities, they not only can integrate into your existing ERP solutions, but also to your PLC infrastructure for the tracking and control of the aforementioned manufacturing processes, as well as for intervening in them. As a “Corporate Member” of the OPC Foundation that determines the standards and realizes the new developments of the OPC infrastructure, which emerged as an international standard for the data of the PLC systems running in the area to be instantly monitored and intervened in and which is the most widespread communication standard today, our infrastructure is ready to “talk to” your PLCs and we are constantly bringing new technologies to an integrated status.

Imagine. You receive an order over web. An information, choice or demand during the order includes a feature (or a parameter during manufacturing) of the demanded product. Afterwards, this order falls to your ERP system. After going through the necessary controls here, it is either issued as a “Production Order” or reaches the officials responsible of manufacturing on the area. At the same time, with our ability to integrate, it falls to the ProMANAGE system. The work order on ProMANAGE is conveyed to our devices in the field and the operator starts this work order using our operator interfaces. At this point, the special demand that the customer made during the order is transferred to the PLC by ProMANAGE and manufacturing realizes in accordance with this feature/parameter. Thanks to this system, the customer’s demand is realized during manufacturing without the necessity of paper forms that roam around, any additional data input and personnel effort. This is magic.

Imagine. You receive an order over web. An information, choice or demand during the order includes a feature (or a parameter during manufacturing) of the demanded product. Afterwards, this order falls to your ERP system. After going through the necessary controls here, it is either issued as a “Production Order” or reaches the officials responsible of manufacturing on the area. At the same time, with our ability to integrate, it falls to the ProMANAGE system. The work order on ProMANAGE is conveyed to our devices in the field and the operator starts this work order using our operator interfaces. At this point, the special demand that the customer made during the order is transferred to the PLC by ProMANAGE and manufacturing realizes in accordance with this feature/parameter. Thanks to this system, the customer’s demand is realized during manufacturing without the necessity of paper forms that roam around, any additional data input and personnel effort. This is magic.

Imagine this one more thing: Your customer conveys a complaint regarding a product. With a single button over an identifier on the product, you can see which process data is used during production and in which machine/area it was produced. And maybe, you immediately convey this problematic process value to your R&D team and make revisions.

The only thing you need for this is for your manufacturing machine to be under PLC control and integrating your PLCs with the ProMANAGE system. Afterwards, all of the process data during manufacturing of all of your products can be recorded and can be traced backwards.

To conclude, your PLCs shouldn’t only remain as “controllers.” The parameters from all manufacturing orders must be “listened” and they should “say” what they are doing via integrating with ProMANAGE. Our technology infrastructure is ready for this. We are ready.